Manyetik Çekme Gücü Kılavuzu: Doğru Gücü Seçin

Choosing the right magnetic snap strength is like finding the perfect key to a lock; it’s vital for ensuring everything fits together seamlessly. You might think any magnet will do, but the truth is that various applications demand specific strengths to avoid failure or damage. Understanding significant metrics like çekme kuvveti ve Gauss can make all the difference in your project’s success. As you consider your options, you’ll want to explore how different magnet grades—like neodymium and ferrite—can impact performance in real-world scenarios. What’s your product really demanding from its magnetic closure? You need a magnetic snap strength guide!

Önemli Çıkarımlar

- Assess the required pull force for your application to ensure effective snap closure and prevent failures.

- Choose neodymium magnets for higher strength and compactness, while ferrite magnets are better for cost-effective, larger applications.

- Ensure adequate surface contact area to maximize magnetic strength and improve performance in closures.

- Consider environmental factors, such as temperature and humidity, which can affect magnet performance and selection.

- Test snap strength during prototyping to refine magnet choice based on user needs and product design.

Why Magnetic Strength Matters in Snap Closures

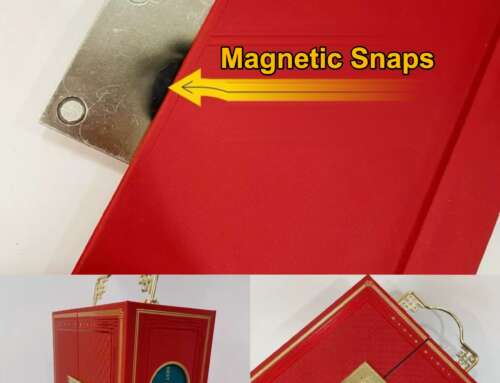

Richarms Square Magnetic Lock tested at 1.1kg of vertical magnetic pull strength.

Magnetic strength in snap closures goes beyond mere attraction; it directly impacts safety and durability.

If the strength isn’t adequate, you risk snap failures, which can lead to fabric damage and misalignment.

Understanding these factors guarantees a reliable user experience and enhances the overall functionality of your product.

Beyond Attraction – Safety, Durability, User Experience

In snap closures, güç plays a vital role not only in attraction but also in ensuring safety ve dayanıklılık. When selecting manyetik çıtçıtlar, understanding their strength is essential for effective performance. This magnetic snap strength guide emphasizes that the correct strength directly affects the closure’s ability to withstand external forces, ensuring the snap remains securely fastened under varying conditions.

A strong magnetic snap prevents accidental disengagement, which could lead to potential hazards or product damage. In high-use applications, durability becomes essential; stronger magnets often exhibit higher resistance to aşınma ve yıpranma. This reliability enhances kullanıcı deneyimi, as users can trust the closure’s functionality without frequent adjustments or replacements.

Utilizing the magnetic snaps strength guide, you can assess the appropriate magnet grade and çekme kuvveti required for your specific application. Whether referring to a guide for magnetic snap strength or a guide for magnetic snaps strength, prioritizing the right specifications will considerably impact both safety and longevity.

Ultimately, informed choices regarding magnetic strength contribute to a seamless user experience, making the right selection not just a matter of preference, but a necessity in design.

Real-World Impact: Failing Snaps, Fabric Damage, Misalignment

Choosing the right strength in manyetik çıtçıtlar directly influences their güvenilirlik in real-world applications. If you opt for a magnet that’s too weak, you risk failure during use, leading to unintended openings. This can result in significant inconvenience, especially in wearable items like bags or clothing.

Over time, weak snaps may also cause fabric damage; repeated strain can wear down the material, creating unsightly tears or deformities.

Misalignment is another critical concern. When snaps lack adequate strength, they may not align properly during closure. This misalignment leads to frustration and inefficiency, making it challenging to secure items effectively.

Additionally, incorrect alignment can compromise the overall aesthetics of the product, affecting user satisfaction and brand perception.

Understanding the specific çekme kuvveti required for your application is vital. For instance, using neodimyum mıknatıslar provides higher coercivity, which helps maintain snap integrity even under various conditions.

Ultimately, selecting the right magnetic strength isn’t just about functionality; it impacts dayanıklılık and user experience. By prioritizing appropriate magnet grades, you guarantee that your snaps perform reliably, preventing failures that could undermine your product’s quality.

Understanding Magnet Ratings and Strengths

To effectively choose the right magnet for your application, you need to understand key metrics like çekme kuvveti, Gauss ratings, and magnet grades, such as N35 versus N52.

The differences between neodymium and ferrite snaps also play a critical role in their performance.

Additionally, consider how surface contact area impacts the overall strength of the connection.

Key Metrics: Pull Force, Gauss, and Grade (e.g. N35 vs N52)

How do the key metrics of çekme kuvveti, Gaussve magnet grade impact your magnet selection process? Understanding these metrics is vital for choosing the right magnet for your application.

Pull force measures the strength of a magnet by quantifying the force required to detach it from a steel surface. This value, typically expressed in pounds, provides a direct indication of a magnet’s effectiveness in your specific context.

Gauss, on the other hand, measures the magnetic field strength at the surface of the magnet. Higher Gauss readings indicate a stronger magnetic field, which is essential for applications requiring precise magnetic activation, like sensors.

Neodymium vs Ferrite Snaps – What’s the Difference?

When comparing neodymium and ferrite snaps, understanding their ratings and strengths is essential for making an informed decision.

Neodymium magnets, designated with grades like N35 to N52, exhibit the highest manyetik güç, characterized by a maximum energy product (BHmax) that can reach up to 55 MGOe. This property makes them ideal for applications requiring compact yet powerful magnets.

In contrast, ferrite magnets, often labeled as ceramic, possess a lower maximum energy product, typically ranging from 1 to 4 MGOe. While ferrite snaps are more uygun maliyetli and resistant to demagnetization, their lower strength means they require larger sizes to achieve comparable pull forces.

Additionally, neodimyum mıknatıslar have better coercivity, making them less susceptible to external magnetic fields, whereas ferrite magnets offer good performance in higher temperatures but lack the same level of strength.

When choosing between these two types, consider your specific application needs—neodymium for strength and compactness, ferrite for budget and temperature resistance. Understanding these differences allows you to select the right magnet for your project with confidence.

Surface Contact Area and Its Role in Strength

Understanding the surface contact area plays a significant role in determining the effective strength of a magnet, particularly when comparing neodymium and ferrite snaps. The larger the contact area between the magnet and the surface, the greater the çekme kuvveti you can expect. This is because a wider surface allows for more magnetic flux lines to interact with the metal, enhancing the overall holding capacity.

When you evaluate magnet strength, remember that surface area isn’t the only factor; the material’s grade and properties also matter. For instance, neodymium magnets, with their higher energy product, can provide substantial strength even in smaller sizes. In contrast, ferrite magnets may require a larger contact area to achieve similar pull forces due to their lower magnetic energy density.

Additionally, the shape of the magnet affects how effectively it distributes its magnetic field across the contact surface. For best performance, make sure that the magnets you choose not only meet your strength requirements but also provide adequate surface contact for your specific application.

Ultimately, understanding these dynamics will help you make informed decisions in selecting the right magnetic snaps for your needs.

Strength Chart by Application (Use Case Based)

When selecting the appropriate magnet strength for your application, understanding the specific use case is essential.

Light-duty applications, like gift cards and paper closures, require considerably lower pull force compared to medium-duty uses such as fabric bags and planners, which need a stronger hold.

İçin heavy-duty scenarios involving thick leather or industrial folders, you must make certain the magnet’s strength aligns with the recommended material thickness to guarantee effective performance.

Light-Duty Use (Thin Lining, Gift Cards, Paper Closures)

While selecting magnets for light-duty applications such as thin lining, gift cards, and paper closures, it is vital to evaluate the specific strength requirements of each use case. These applications typically need magnets that provide sufficient holding strength without overwhelming the materials involved.

Here’s a strength chart for better understanding:

| Uygulama | Suggested Magnet Grade | Pull Force (lbs) |

|---|---|---|

| Thin Lining | N35 | 1-2 |

| Gift Cards | N42 | 2-3 |

| Paper Closures | N35 | 1-2 |

In these scenarios, using lower-grade neodymium magnets (like N35 or N42) is often sufficient. They offer adequate pull force while maintaining a slim profile, which is essential for aesthetics in items like gift cards. Also, consider the environmental conditions when selecting a magnet; humidity or extreme temperatures might affect performance. Always verify the chosen magnet meets the specific requirements of your application to achieve peak functionality and durability.

Medium-Duty Use (Fabric Bags, Planners, Small Leather Goods)

İçin medium-duty applications like fabric bags, planners, and small leather goods, selecting the right magnet grade becomes increasingly significant as the demands for strength and durability rise.

You’ll typically want to take into account neodimyum mıknatıslar, particularly grades like N42 or N52, depending on the specific requirements of your product.

N42 offers a balanced approach regarding strength and cost, while N52 provides the highest strength in the smallest form factor at room temperature.

However, if your application experiences temperature fluctuations, N42 may perform better in the 140°F to 176°F range.

It’s essential to assess the çekme kuvveti required to guarantee that the magnetic closure remains secure during everyday use.

Typically, a pull force of 3 to 5 pounds is sufficient for fabric bags and planners, but adjust this based on your product’s design and user interactions.

Lastly, evaluate the magnetic field strength; a surface field of at least 300 Gauss is ideal for reliable operation, especially in products that rely on sensors like reed switches.

Heavy-Duty Use (Thick Leather, Industrial Folders, Rigid Boxes)

As you consider heavy-duty applications like thick leather goods, industrial folders, and rigid boxes with magnetic gift box closure, selecting the appropriate magnet grade is vital for guaranteeing durability and performance.

For these applications, you’ll want to focus on higher grades, typically N42 or N52 neodymium magnets, due to their superior strength-to-size ratio. These magnets deliver the necessary çekme kuvveti to hold heavy materials securely while resisting demagnetization under stress.

When evaluating your needs, assess the thickness of the materials involved. The thicker the leather or the more rigid the box, the stronger the magnet you’ll require to guarantee a güvenilir kapatma.

Keep in mind that çevresel faktörler, such as temperature and moisture, can also impact magnet performance; thus, choose magnets with suitable temperature resistance if exposure to extreme conditions is likely.

Additionally, consider the design of your product. The shape and placement of the magnets can influence their effectiveness.

Understanding these parameters allows you to make informed decisions, guaranteeing that your heavy-duty applications function effectively and meet performance expectations consistently.

This careful selection process is vital to achieving long-lasting, reliable results in your projects.

Table: Snap Type × Pull Force × Recommended Material Thickness

Understanding the relationship between snap type, çekme kuvveti, and recommended material thickness is critical for enhancing magnet performance in heavy-duty applications. This table serves as a practical reference, allowing you to evaluate which snap type best meets your project’s demands based on pull force and material thickness.

You’ll find that different snap types, such as neodymium veya ceramic, have varying pull forces, which directly influences their effectiveness. For example, a neodymium snap may require a material thickness of at least 1/8 inch to guarantee peak adhesion, depending on its pull force rating.

In contrast, a ceramic snap might be effective at a thinner material, but its overall pull force will typically be lower, requiring you to factor in the trade-off between thickness and strength.

When selecting your magnets, refer to the pull force values in the table to match your specific application requirements. This guarantees that the chosen magnet not only adheres properly but also withstands the operational demands of your project, whether that be in thick leather goods or industrial folders.

Always prioritize matching the right snap type with the appropriate material thickness for maximum efficiency.

Design Tips: How to Match Snap Strength to Your Product

When designing your product, it’s essential to match the snap strength of the magnets to your specific application.

If the strength is too low, you’ll face issues like slips and misalignment, while overly strong magnets may make it difficult to open or even tear materials.

Testing snap strength during prototyping can help you identify the ideal balance for your design needs.

What Happens If Strength is Too Low? (Slips, Misalignment)

Insufficient magnetic strength can lead to significant issues such as slips and misalignment in your product’s design. When the magnetic force isn’t strong enough to hold components together, you risk frequent disconnections, causing operational failures. This can compromise kullanıcı deneyimi, particularly in applications where precision is critical, such as electronic devices or automotive components.

Misalignment occurs when magnets fail to engage properly, resulting in parts not fitting together as intended. This can create gaps, leading to performance degradation or even complete product failure. For example, in assemblies requiring tight tolerances, a weak magnetic connection can disrupt functionality, necessitating costly redesigns or repairs.

To prevent these issues, accurately assess the required pull force and select a magnet grade that meets your specific application needs. Consider factors like weight, environmental conditions, and the forces that may act on the magnets during use.

What Happens If Too Strong? (Hard to Open, Material Tear)

Often, using magnets with excessive strength can create practical challenges in product design. When the magnetic snap is too strong, users may struggle to open the product, leading to frustration and potential misuse. This difficulty can deter customers from engaging with your product, ultimately impacting its marketability.

Moreover, an overly strong magnetic connection can put undue stress on the materials involved. If the materials aren’t designed to withstand such forces, you risk tearing or damaging them. This could result in costly replacements and repairs, as well as damage to your brand’s reputation for quality.

In addition, consider how excessive strength can affect assembly and manufacturing processes. If components are difficult to align or require excessive force to connect, it could slow down production and increase labor costs.

To avoid these pitfalls, it’s essential to strike a balance in magnet strength. Assess the intended use, user capabilities, and environmental conditions to select a magnet that provides adequate holding power without compromising usability or material integrity.

Ultimately, aligning snap strength with your product’s functional requirements will enhance both performance and user satisfaction.

How to Test Snap Strength During Prototyping

Balancing magnetic snap strength is essential for ensuring user satisfaction and material integrity, particularly during the prototyping phase. To achieve this, you should systematically test the snap strength of the magnets you intend to use. Start by measuring pull force using a calibrated force gauge, ensuring consistent conditions. Conduct tests with different grades of magnets to evaluate performance variations.

Here’s a simplified testing guide:

| Magnet Grade | Pull Force (lbs) |

|---|---|

| N52 | 20 |

| N42 | 15 |

| C8 | 10 |

| SmCo | 12 |

| C2 | 8 |

Next, apply the pull force measurements to assess the user experience. Consider how easy or difficult it is to engage and disengage the magnets. Adjust the magnet grade based on feedback and performance. If users struggle to open the mechanism, consider a weaker grade or altering magnet placement.

Richarms’ Magnetic Snap Options by Strength

Richarms offers a range of manyetik çıtçıtlar tailored to different applications, categorized by strength.

İçin light-duty needs, the pvc magnetic snaps Round Snaps provide adequate hold without compromising aesthetics.

In contrast, the Square Double-Rivet Magnetic Snap serves mid-duty applications, while the strongest neodymium snap is designed for heavy-duty use, ensuring reliable performance under demanding conditions.

Light-Duty: PVC Invisible Round Snaps

Seçerken magnetic snap options için light-duty applications, PVC invisible round snaps offer an effective solution that combines functionality with aesthetic appeal.

These snaps are designed for applications where minimal force is required while maintaining a seamless appearance. Their construction typically utilizes neodimyum mıknatıslar, known for their strong pull force, despite the compact size.

You’ll find that these snaps are particularly well-suited for items like clothing, bags, and lightweight closures. The PVC material not only provides durability but also enhances the snap’s invisibility, making it a popular choice for designers focused on clean lines.

In terms of strength, it’s crucial to take into account the pull force rating, which directly impacts how well the snap will function in your specific application. For light-duty uses, the pull force typically ranges between 1 to 3 pounds, sufficient for holding lightweight fabrics without compromising ease of use.

When evaluating options, make sure you assess the magnet grade, as this can affect the snap’s performance under varying conditions.

Mid-Duty: Square Double-Rivet Magnetic Snap

Magnet strength plays an essential role in the effectiveness of mid-duty applications, and the Square Double-Rivet Magnetic Snap exemplifies this principle. Designed for robust functionality, this snap uses a neodimyum mıknatıs, guaranteeing a strong hold while maintaining ease of use.

Its square shape enhances surface contact, maximizing çekme kuvveti and stability in various applications, like bags or clothing. When selecting the Square Double-Rivet Snap, consider its pull force, typically measured in pounds. This measurement directly correlates to the magnet’s grade; for instance, an N42 grade might provide a balanced performance between strength and cost.

You’ll find that this snap’s design minimizes accidental disengagement, thanks to its double-rivet construction, which secures the magnet effectively. Another crucial factor is the environmental conditions. The Square Double-Rivet Magnetic Snap generally withstands moderate temperatures, but always consult the specifications to guarantee peak performance.

Understanding the properties of remanence and coercivity is fundamental, as these will affect your snap’s longevity and reliability in practical applications. By emphasizing these characteristics, you can confidently choose the right mid-duty magnetic snap for your needs.

Heavy-Duty: Strongest Neodymium Snap

A heavy-duty magnetic snap is fundamental for applications requiring maximum strength and reliability, and Richarms offers some of the strongest neodymium snap options available.

When selecting a neodymium snap, consider the N52 grade, which provides the highest magnetic strength in a compact size. This grade excels in environments where space is limited but robust holding power is necessary.

Richarms also provides options with elevated temperature resistance, particularly the N42SH grade, suitable for conditions up to 176°F. These high-performance magnets maintain their coercivity and remanence, guaranteeing consistent functionality even under stress.

Measuring çekme kuvveti is essential for evaluating magnet strength; Richarms�?heavy-duty snaps can exhibit pull forces exceeding 100 pounds, making them ideal for demanding applications.

It’s crucial to assess the specific pull force required for your project, as this guides the selection process and guarantees optimal performance.

Understanding the hysteresis curve associated with these magnets allows you to predict behavior under varying conditions.

Expert Tips from Magnetic Material Science

To optimize your use of magnets, you should consider insights from magnetic domain theory and the effects of environmental factors like heat and moisture.

Anlamak field leakage is essential for maintaining magnetic performance in various applications.

Insights from Magnetic Domain Theory

Anlamak magnetic domain theory offers essential insights into how materials exhibit their magnetic properties, fundamentally influencing the performance of various magnets. Each magnetic material comprises numerous domains, which are small regions where the magnetic moments of atoms align uniformly. When these domains align in the same direction, the material exhibits significant magnetization.

You need to recognize that the alignment of these domains can be affected by external factors like temperature and magnetic fields. If you apply an external magnetic field, it can cause the domains to align, enhancing the material’s overall magnetic strength. Conversely, if the external field is removed, some domains may return to random orientations, resulting in a loss of magnetization.

Coercivity plays a crucial role here; materials with high coercivity retain their magnetization better than those with low coercivity. For instance, neodimyum mıknatıslar, with their high coercivity, maintain a strong magnetic field even when subjected to demagnetizing influences.

Understanding these domain behaviors helps you select the right magnet type for your applications, ensuring you achieve maximum performance based on the material’s magnetic characteristics.

Heat, Moisture, and Field Leakage Considerations

Maintaining ideal magnetic performance requires careful consideration of heat, moistureve field leakage.

Temperature fluctuations can greatly affect a magnet’s strength, leading to potential demagnetization. For example, neodimyum mıknatıslar lose their magnetic properties when exposed to elevated temperatures beyond their rated limits. Always check the temperature resistance of your chosen magnet grade to verify it meets your application requirements.

Moisture is another critical factor. Many magnets, especially neodymium, are susceptible to corrosion when exposed to humidity. To mitigate this risk, consider using coatings or encapsulation to protect the magnet from environmental factors.

Field leakage can also impact magnetic performance. This phenomenon occurs when the magnetic field extends beyond the intended area, potentially interfering with nearby electronic components or sensors.

To minimize field leakage, design the magnet’s housing carefully and use magnetic shielding materials when necessary.

Tips from and

Exploring the intricate relationship between magnetic materials and their domains reveals vital insights for optimizing magnet performance. The alignment of magnetic domains greatly influences the overall magnetic properties of materials.

To enhance magnet strength, consider utilizing neodimyum mıknatıslar, known for their high coercivity and remanence. Their ability to maintain magnetization under varying conditions is essential in many applications.

When selecting a magnet, examine the BH curve, which illustrates the relationship between magnetic field strength and magnetization. Focus on the second quadrant of the curve; it indicates operational behaviors important for your intended application.

Additionally, understand the impact of temperature on magnetic performance. For instance, certain grades like N42 may perform better under elevated temperatures compared to their stronger counterparts.

Lastly, make sure your application context is considered. Factors such as surface area and shape can alter pull force measurements and overall effectiveness.

Conclusion: Match Strength to Material – Not Guesswork

To guarantee ideal performance, it’s essential to match magnet strength with the specific material requirements of your application.

Relying on generalizations can lead to inefficiencies and failures.

For tailored solutions, consider contacting Richarms to discuss custom invisible magnetic buttons strength designs that meet your exact needs.

Recap key principles

Matching magnet strength to material isn’t just a matter of guesswork; it requires a clear understanding of magnet grades, properties, and application requirements. To guarantee peak performance, you need to take into account factors such as material type, temperature resistance, and specific application needs. Here’s a quick reference to help you navigate the key principles:

| Magnet Grade | Key Feature |

|---|---|

| N52 | Highest strength at room temp |

| N42 | Cost-effective balance |

| N42SH | High-performance at elevated temp |

| SmCo | Excellent high-temp stability |

| Ceramic | Cost-efficient for lower strength |

Understanding these grades allows you to match the magnetic strength to your materials. Remember that the pull force can vary based on the testing conditions and application context. Always evaluate the magnetic field strength in relation to its intended use, particularly when activating sensors like reed switches. By applying these principles, you’ll make informed decisions that enhance functionality and safety, minimizing the risk of magnet failure in your projects. Trust in the data, and you’ll find the right magnet for your needs.

Recommend contacting Richarms for custom magnet strength design

Söz konusu olduğunda custom magnet strength design, relying on standard options mightn’t meet your specific requirements. You need to take into account factors such as material type, application environmentve desired pull force.

Each magnet grade, whether neodymium, ceramic, or samarium cobalt, has unique properties that affect performance, especially under varying temperatures and external magnetic fields.

To achieve ideal results, it’s essential to tailor magnet specifications precisely to your application. That’s where Richarms comes into play.

Their expertise in custom magnet strength design allows you to discuss your specific needs directly with professionals who understand the technical intricacies involved. They can guide you through selecting the appropriate grade and configuration, ensuring that your magnets deliver the necessary strength without compromising safety or functionality.

Sıkça Sorulan Sorular

What Safety Measures Are Needed When Handling Strong Magnets?

When handling strong magnets, you’ve got to treat them like wild beasts. Always wear gloves, keep them away from electronics, secure them in storage, and never let them snap together; injuries can be severe.

How Do Environmental Factors Affect Magnet Performance?

Environmental factors like temperature and humidity greatly impact magnet performance. High temperatures can demagnetize, while moisture can lead to corrosion. You need to take into account these variables to maintain ideal magnet strength in your applications.

Can Magnets Lose Strength Over Time?

Yes, magnets can gradually lose their charm over time due to factors like temperature fluctuations, physical stress, or environmental exposure. Monitoring these influences guarantees peak performance, maintaining the magnetic allure you rely on for various applications.

What Are the Risks of Using Incorrect Magnet Grades?

Using incorrect magnet grades can lead to insufficient performance, safety hazards, and potential equipment failure. It’s crucial you understand the specific requirements of your application to avoid costly mistakes and guarantee peak functionality.

How Do I Properly Dispose of Old Magnets?

To properly dispose of old magnets, check local regulations. Most can be recycled with metals. For neodymium magnets, consider returning them to the manufacturer or a specialized recycling facility to prevent environmental hazards.

Sonuç

Choosing the right manyetik güç for your snap closures is like finding the perfect key for a lock; it guarantees a seamless fit and reliable function. Just as a key that’s too large can jam the mechanism, an overly strong magnet can damage materials or misalign components. By carefully matching magnet strength to your product’s requirements, you can enhance durability and kullanıcı deneyimi, assuring that your design operates flawlessly without unnecessary complications. Don’t leave it to chance—be precise in your selection.