Type: Permanent Magnets

Composite: Neodymium Magnet

Shape: make as order

Application: Industrial Magnet

Coatings: Ni, Zn, gold, silver, copper, epoxy, and so on

Tolerance: +/-0.03 to +/-0.15

Shapes: Arc/Disc/Bar/Block…

Grade: N3N35M-N52M,N35H-N50H,N33SH-N45SH

Sizes: customized

magnetize direction: Customized

delivery: by sea, by air, or by express

Temperature: The max operation temp is up to 230 d

Segment Magnet Factory

Description

Segment NdFeB Magnet | Custom Industrial Magnets for Diverse Applications

Material: NdFeB (Neodymium)

Shape Options: Disc, Cylinder, Block, Ring, Countersunk, Segment, Trapezoid, and more custom shapes

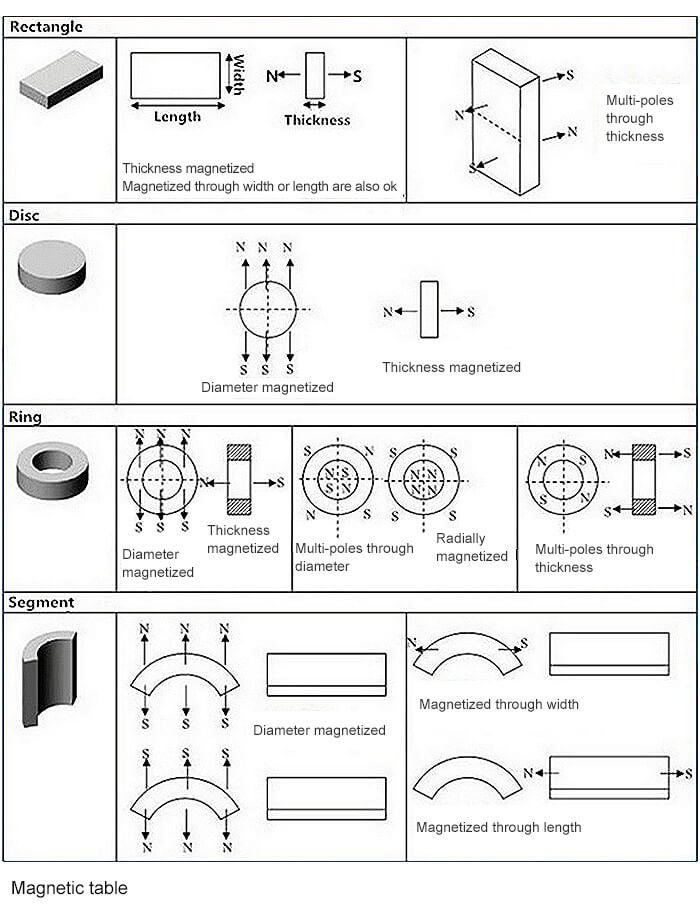

Magnetization Direction: Thickness Magnetized or Radially Magnetized (customizable)

Coating Options: Nickel (Ni), Zinc (Zn), Gold, Silver, Copper, Epoxy and more

Size and Tolerance: Custom sizes with tolerances ranging from +/-0.03mm to +/-0.15mm

Working Temperature: Maximum operating temperature up to 230°C based on grade

Delivery: Small order available, Available by sea, air, or express delivery

| Type | Permanent |

| Composite | NdFeB Magnet |

| Shape | Disc, Cylinder, Block, Ring, Countersunk, Trapezoid |

| Ir-regular shapes and more custom shapes | |

| Application | Industrial Magnet |

| Magnetize direction | Customized |

| Size | Customized |

| Coating | Ni, Zn, gold, silver, copper, epoxy, and so on |

| Tolerance | +/-0.03 to +/-0.15 |

| Working temperature | The max operation temp is up to 230 degree centigrade |

| Delivery | By sea, by air, or by express |

| Max Working Temperature | Grade |

| 80°C | N33-N52 |

| 100°C | N35M-N45M |

| 120°C | N33H-N50H |

| 150°C | N33SH-N45SH |

| 180°C | N30UH-N42UH |

| 200°C | N30EH-N38EH |

| 230°C | N28AH-N33AH |

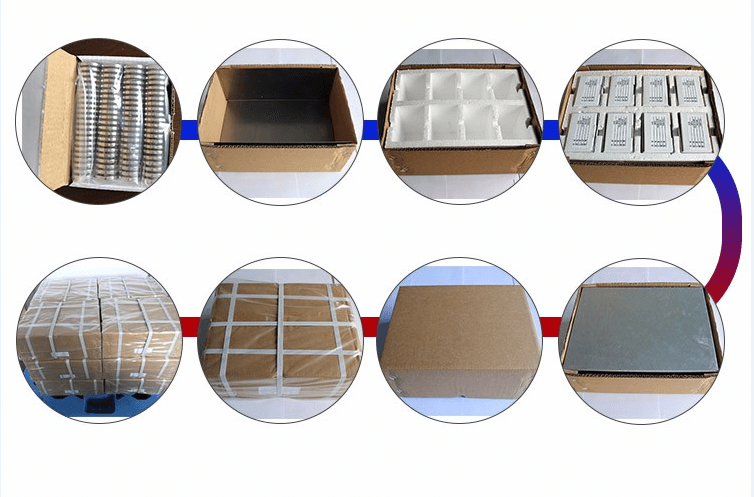

NdFeB magnets securely packaged in small white boxes, ensuring safe transport and easy handling.

Packaging:

NdFeB magnets undergo a careful de-magnetization packaging process, involving layers of iron boxes, foam, and paper boxes to ensure secure transport.

Understanding the two magnetization directions for NdFeB magnets: Thickness Magnetized and Radially Magnetized.

Magnetization Direction:

Thickness Magnetized

Radially Magnetized

Key Features of Segment NdFeB Magnets:

- Customizable for Industrial Applications: Our Segment NdFeB magnets are highly versatile and can be customized in terms of size, shape, magnetization direction, and coating. They are designed to meet your specific application needs in industrial settings.

- High-Performance and Temperature Resistance: These magnets offer exceptional magnetic strength and can withstand a wide range of temperatures, with certain grades reaching up to 230°C in high-temperature environments. Perfect for applications in motors, sensors, and electronic devices.

- Available in Various Shapes: Choose from a wide range of shapes such as discs, cylinders, blocks, and segments, with custom designs available for more specialized requirements. Whether you need a trapezoid, ring, or countersunk magnet, we’ve got you covered.

- Efficient Delivery: With flexible delivery options, we ensure timely shipping via sea, air, or express services to meet your project timelines.

Why Choose Our Segment NdFeB Magnets?

- Custom Magnetization: Our Segment NdFeB magnets can be magnetized in different directions, including thickness or radial magnetization, to suit your specific application.

- Durable and Reliable: With a variety of coatings such as nickel, zinc, gold, and epoxy, these magnets are protected against corrosion, ensuring long-term durability.

- Superior Strength and Efficiency: Known for their strong magnetic properties, NdFeB magnets provide excellent performance across a wide range of industries, including electronics, automotive, manufacturing, and energy.