Magnetic Connectors for Medical & Wearable Devices

Did you know that nearly 70% of medical devices now incorporate some form of magnetic connectivity? This shift highlights the growing importance of magnetic electronic connectors in enhancing the functionality and reliability of medical and wearable devices. As you consider the implications of this trend, think about how these connectors can revolutionize patient care and health monitoring systems. What factors should you consider when choosing the right connector for your specific needs?

Key Takeaways

- Magnetic electronic connectors enhance the safety and functionality of medical and wearable devices with their breakaway and waterproof features.

- These connectors ensure reliable connections for health tech applications, facilitating efficient patient care and treatment effectiveness.

- The low-resistance characteristics of magnetic connectors improve power and data transmission, essential for critical medical applications.

- Customization options, including magnet strength and shape, allow for tailored solutions that meet specific device requirements.

- Rapid prototyping and low minimum order quantities enable quick market entry and design adjustments based on user feedback.

What Are Magnetic Connectors and Why They Matter

A variety of magnetic connector designs—from single-pole to multi-pin interfaces—used in health monitoring, therapy, and wearable tech.

Magnetic connectors offer significant advantages over traditional connectors, particularly in medical and wearable devices. Their breakaway feature enhances user safety by preventing injuries during accidental pulls. Waterproof designs guarantee durability in various environments. Additionally, low-resistance characteristics facilitate efficient power and data transmission, making these connectors essential for reliable device performance.

Benefits Over Traditional Connectors

In the field of electronic connectors, magnetic connectors stand out due to their unique benefits over traditional options. By employing magnetic forces for connection, these magnetic electronic connectors facilitate a quick and effortless mating process. This not only enhances user experience but also reduces the risk of accidental disconnections, which is vital in medical settings where reliability is paramount.

Unlike traditional connectors that may suffer from wear and tear, magnetic electronic connectors boast longer lifespans, often exceeding 30,000 mating cycles. Their precision machined components guarantee low resistance, maintaining efficient current flow and minimizing energy loss.

Additionally, the tear-away design inherent in many magnetic connectors safeguards against damage during unexpected pulls, enhancing both user safety and equipment longevity.

Furthermore, the streamlined design of magnetic connectors promotes ease of cleaning and sterilization, addressing important hygiene concerns in medical environments. By minimizing exposed parts, they reduce debris accumulation, ultimately improving infection control. With these advantages, magnetic connectors are paving the way for more reliable, user-friendly, and safe electronic connections in both medical and wearable devices, ensuring a higher standard of care and efficiency.

Breakaway, Waterproof, Low-Resistance Features Explained

The integration of breakaway, water-repellent, and low-friction features in connectors greatly enhances their functionality and safety, especially in demanding environments like medical applications.

Breakaway designs allow connectors to disconnect under tensile force, preventing injury or damage during unexpected pulls. This is essential in medical settings where patient safety is paramount.

Water-repellent characteristics guarantee that the connectors maintain their integrity in environments prone to moisture, facilitating effective cleaning and disinfection. Achieving an IPX8 rating means these connectors can withstand continuous immersion in water, making them ideal magnetic connectors for medical device exposed to liquids.

Low-friction features are necessary for ensuring efficient power transfer and data communication. These connectors minimize energy loss, supporting continuous and stable performance, which is crucial in life-saving medical devices. By reducing resistance, they enhance the reliability of critical applications, such as patient monitoring systems and surgical tools.

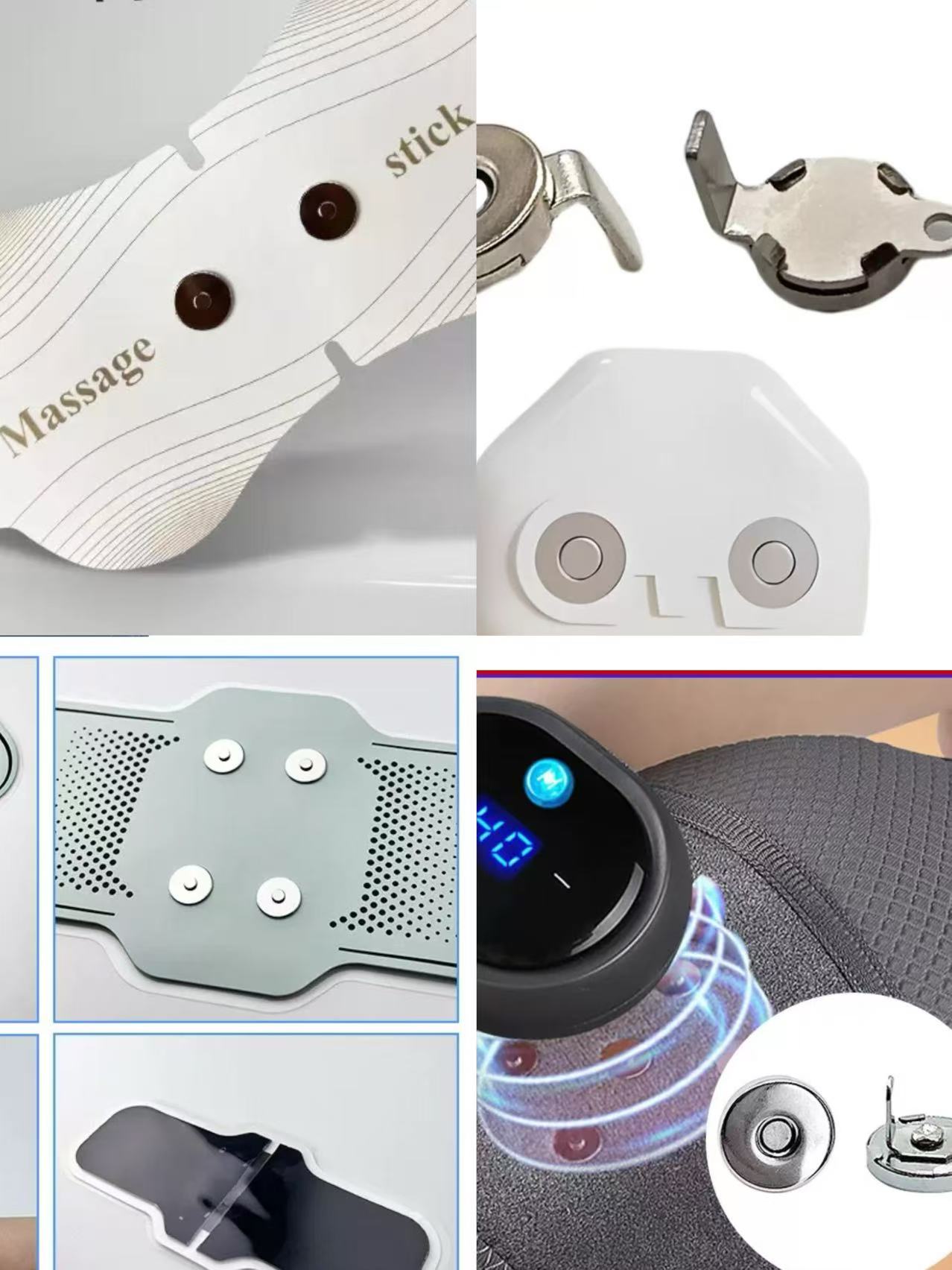

Key Applications in Health Tech

Examples of magnetic snap connectors in smart health wearables—ideal for EMS massagers, heating pads, and flexible therapy electronics.

In health tech, magnetic electronic connectors play an essential role in enhancing the functionality of wearables, such as neck and body massagers. These connectors streamline the integration of hospital equipment and home therapy devices, ensuring reliable and efficient connections. By facilitating quick and secure linkages, they contribute notably to patient care and treatment effectiveness.

Wearables: Neck & Body Massagers

While exploring advancements in health tech, wearables like neck and body massagers have emerged as essential solutions for improving well-being and pain management. These devices leverage innovative technology to deliver therapeutic benefits, making them vital in the modern healthcare landscape. By incorporating magnetic electronic connectors, these massagers guarantee reliability and ease of use.

Here are four key benefits of neck and body massagers:

- Targeted Pain Relief: They provide focused treatment to alleviate tension and discomfort in specific areas, enhancing user comfort.

- Customizable Settings: Most devices offer adjustable intensity and massage modes, allowing users to tailor their experience to individual needs.

- Portable Design: Many massagers are lightweight and easy to carry, enabling on-the-go relief wherever you are.

- User-Friendly Interface: With intuitive controls and often wireless functionality, these devices are accessible for all ages.

As healthcare continues to prioritize patient-centered approaches, wearable massagers play an essential role in empowering individuals to manage their health actively. Their integration of magnetic connectors further enhances connection stability, ensuring consistent performance and user satisfaction.

Hospital Equipment

Wearable technology, like neck and body massagers, exemplifies the integration of health tech innovations into everyday life, particularly in hospital settings where efficient and reliable equipment is crucial.

Magnetic electronic connectors play a pivotal role in hospital equipment, guaranteeing seamless interactions between devices such as patient monitors and diagnostic tools. These connectors feature a low resistance design, which ensures consistent power flow and reliable data transfer.

In clinical environments, the use of magnetic connectors reduces the risk of damage due to frequent connections and disconnections. Their quick mating capabilities allow for easy setup and maintenance, facilitating rapid equipment changes necessary in urgent medical situations. Furthermore, the tear-away feature enhances patient safety by preventing injuries from accidental disconnections.

These connectors also support strict infection control measures by minimizing exposed parts, which aids in easier cleaning and sterilization. Enhanced durability and reduced wear and tear guarantee that your equipment remains functional over time. Ultimately, incorporating magnetic connectors into hospital equipment not only improves operational efficiency but also contributes to higher standards of patient care and safety.

Home Therapy Devices

Home therapy devices are revolutionizing personal health management by integrating advanced technologies that enhance therapeutic outcomes. These devices empower you to take control of your health in the comfort of your own home, guaranteeing consistent and effective treatment. With the incorporation of magnetic electronic connectors, these devices have become more reliable and user-friendly.

Consider the following key features:

- Ease of Use: Magnetic connectors facilitate quick attachment and detachment, minimizing user frustration.

- Safety Features: Breakaway mechanisms prevent accidental disconnections, reducing the risk of injury.

- Durability: High-quality materials guarantee long-lasting performance, even with frequent use.

- Compatibility: These devices can integrate seamlessly with various health monitoring systems, enhancing their functionality.

- As you explore home therapy options, prioritize devices that utilize magnetic connectors. They not only simplify interactions but also promote safety and efficiency in your therapeutic routines. By leveraging these innovations, you can better serve your health needs and improve your overall well-being.

Embrace the future of personal health management with confidence, knowing that technology is working to support your healing journey.

How to Choose the Right Magnetic Connector

An array of wearable and diagnostic medical components using magnetic connectors for compact, safe, and efficient power/data transfer.

When selecting a magnetic connector, consider the pole type, choosing between single or dual configurations based on your requirements.

Evaluate the connection style—whether board-to-cable, Pogo pin, or snap button—to guarantee compatibility with your device.

Additionally, assess the environment where the connector will be used, focusing on IP ratings and anti-reverse needs for peak performance.

Pole Type: Single vs Dual

Choosing the right magnetic connector involves understanding the differences between single pole and dual pole types, as each offers distinct advantages for specific applications. When deciding which to use, consider the following criteria:

- Current Requirements: Single pole connectors are often sufficient for low-power applications, while dual pole connectors can handle higher currents, making them ideal for medical devices requiring more power.

- Connection Stability: Dual pole connectors provide greater stability, especially in environments where movement may disrupt the connection. This guarantees consistent performance in wearable devices.

- Size Constraints: If space is limited, single pole connectors might be a better fit due to their compact design. Dual pole connectors, while larger, offer enhanced functionality.

- Safety Features: For critical applications, dual pole connectors often include additional safety measures, such as breakaway capabilities, which minimize risks during disconnection.

Connection Style: Board-to-Cable / Pogo Pin / Snap Button

Magnetic connector selection hinges on understanding the nuances of connection styles: board-to-cable, pogo pin, and snap button. Each style serves specific needs within medical and wearable devices, impacting reliability and user experience.

Board-to-cable connectors are ideal for applications requiring a robust connection between a circuit board and external components. They provide excellent durability and stability, making them suitable for devices with frequent connections and disconnections.

Pogo pins, on the other hand, offer high reliability with a long lifespan, often exceeding 100,000 mating cycles. Their spring-loaded mechanism ensures consistent contact, which is essential in medical devices where maintaining a reliable connection can impact patient safety and device performance.

Snap button connectors facilitate quick and easy mating, providing a user-friendly interface. These connectors are particularly beneficial in wearable devices, where ease of use is paramount for patient compliance.

When choosing the right magnetic connector, assess your application’s specific requirements, including environmental factors and operational frequency. By understanding these connection styles, you can make informed decisions that enhance the functionality and safety of your medical or wearable device.

Environment: IP Rating / Anti-Reverse Needs

In environments where moisture and dust are prevalent, understanding the IP (Ingress Protection) rating of a magnetic connector is essential for guaranteeing device reliability and longevity. An appropriate IP rating safeguards your devices against environmental hazards, especially in medical and wearable applications. Here’s how to choose the right magnetic connector based on IP ratings and anti-reverse needs:

- Assess Environmental Conditions: Identify the specific exposure to dust and moisture your device will face.

- Select IP Ratings: Look for connectors with at least IP65 for dust-tight and water-resistant capabilities, or IP67/IP68 for full immersion protection.

- Consider Anti-Reverse Features: Guarantee the connector design prevents incorrect connections, which can lead to device malfunction or damage.

- Evaluate Durability: Opt for connectors that can withstand high mating cycles while maintaining performance, especially in high-use scenarios.

Richarms Connector Portfolio

Close-up view of various custom-designed magnetic connectors crafted for advanced medical and wearable electronics.

In exploring the Richarms Connector Portfolio, you’ll find a diverse range of options categorized by function, design, and application.

This includes connectors specifically tailored for data, power, or hybrid uses, along with various designs such as spring pins and RJ45.

Whether you’re working on a mini massager, PCB, or health monitor, selecting the right connector is essential for peak performance and reliability.

By Function: Data, Power, Hybrid

Richarms offers a diverse portfolio of connectors categorized by their specific functions: data, power, and hybrid. This classification allows you to choose the right connector based on your application needs, enhancing both performance and reliability in medical and wearable devices.

Here’s a brief overview of each type:

- Data Connectors: These connectors facilitate high-speed data transfer while ensuring minimal signal loss. They’re essential for applications requiring quick and accurate information exchange.

- Power Connectors: Designed to efficiently deliver power, these connectors support stable connections even in demanding environments. They maximize energy flow, ensuring devices operate effectively.

- Hybrid Connectors: Combining data and power capabilities, hybrid connectors streamline connections, reducing the need for multiple interfaces. This dual-functionality simplifies design and assembly.

- Customization Options: Richarms connectors can be tailored to meet specific requirements, ensuring compatibility with various medical and wearable devices.

By Design: Spring Pins, Flat Snap, RJ45

Connecting devices effectively requires an understanding of various connector designs, particularly when it comes to medical and wearable applications. The Richarms connector portfolio features three primary designs: spring pins, flat snap, and RJ45. Each design serves specific purposes that enhance reliability and usability in critical environments.

Spring pins offer a robust solution with their spring-loaded contacts, ensuring stable connections even under movement. These connectors excel in situations where frequent mating and un-mating occur, such as in wearable devices, providing long life spans of up to 30,000 cycles.

Flat snap connectors provide a user-friendly interface, allowing for quick and secure connections. They’re particularly beneficial in medical settings, where ease of use is paramount for both operators and patients.

RJ45 connectors are important for data applications, supporting high-speed data transfer essential in healthcare monitoring systems. Their design minimizes connection errors, ensuring accurate and reliable data transmission.

By Application: Mini Massager, PCB, Health Monitor

When designing applications like mini massagers, PCBs, and health monitors, the choice of connectors plays an essential role in ensuring functionality and reliability. Magnetic connectors excel in these applications due to their robust performance and user-friendly design. Here are some key advantages:

- Quick Mating: The magnetic force allows for fast and effortless connections, enhancing user experience.

- Durability: With a lifespan of up to 30,000 mating cycles, these connectors are built to withstand frequent use, making them ideal for consumer electronics.

- Safety Features: The tear-away design prevents accidental disconnections, safeguarding both the device and the user.

- Compact Design: Their small footprint enables integration into tight spaces, which is vital for health monitors and wearable devices.

OEM & Custom Projects

Richarms engineers meticulously designing magnetic connectors for precision medical and wearable device applications.

When it comes to OEM and custom projects, you can benefit from low minimum order quantities and rapid prototyping to suit your specific needs.

You have the flexibility to customize magnet strength, shape, and encapsulation to enhance the functionality of your devices.

For tailored solutions, don’t hesitate to consult with our experts to discuss your project requirements.

Low MOQ & Fast Prototyping

For businesses seeking to innovate in the medical and wearable device sectors, low minimum order quantities (MOQs) and fast prototyping capabilities are essential. These features allow you to quickly iterate on designs, reducing the time to market while minimizing financial risk.

Here are four key benefits of low MOQs and rapid prototyping:

- Cost Efficiency: Lower MOQs mean you can test new products without committing to large quantities, keeping your upfront costs manageable.

- Speed to Market: Fast prototyping accelerates your development process, allowing you to bring innovative solutions to healthcare challenges sooner.

- Customization Flexibility: You can easily make design adjustments based on user feedback, ensuring your products meet specific needs and preferences.

- Risk Mitigation: With smaller production runs, you can gauge market response before scaling up, reducing the risk of overproduction and wasted resources.

Custom Magnet Strength, Shape, Encapsulation

Customizing magnet potency, form, and shielding is pivotal for optimizing performance in OEM and custom projects, especially in the medical and wearable device sectors. You’ll want to take into account the specific requirements of each application to guarantee reliable and efficient connections.

Potency is key; too weak and connections may fail, too strong and you might make disengagement difficult. By selecting the appropriate magnet potency, you can achieve the perfect balance for your device’s operational needs.

Form also plays a significant role. Custom shapes can enhance the alignment and mating process, ensuring quick, accurate connections that are essential in time-sensitive medical environments.

Talk to Our Expert + Form Embed

Your project deserves tailored solutions that meet the intricate demands of OEM and custom applications in the medical and wearable device sectors. Engaging with our experts can guarantee you receive the precise guidance needed to develop innovative magnetic electronic connectors. We focus on providing you with solutions that enhance functionality, safety, and patient care.

Here’s how we can assist you:

- Custom Design: Collaborate on connector specifications that align with your unique requirements.

- Rapid Prototyping: Utilize our streamlined processes to produce quick prototypes, speeding up your development cycle.

- Technical Support: Access our knowledgeable team for ongoing support throughout your project, ensuring seamless integration.

- Quality Assurance: Rely on our rigorous testing protocols to ensure the durability and reliability of your connectors.

Don’t leave your project to chance. Connect with our experts to discuss your OEM and custom projects. Fill out our embedded form today, and let’s set out on creating solutions that meet your needs and elevate your device’s performance in the healthcare arena. Your vision can become a reality with the right partnership.

Frequently Asked Questions

Do Magnetic Connectors for Medical Devices Enhance Patient Safety?

Magnetic connectors enhance patient safety by reducing exposure to sharp pins, facilitating quick disconnections during emergencies, and enabling one-handed operations. These features minimize risks, support efficient cleaning, and ultimately improve overall treatment accuracy and patient care.

What Are the Maintenance Requirements for Magnetic Connectors?

To maintain magnetic connectors, you should regularly inspect for wear, clean contact surfaces, and guarantee proper alignment. You’ll want to avoid exposure to moisture and contaminants to preserve performance and extend their lifespan.

Can Magnetic Connectors Be Used in High-Temperature Environments?

Yes, magnetic connectors can operate in high-temperature environments, provided they’re designed with heat-resistant materials. Confirm you check the specifications to confirm their thermal limits, optimizing performance and reliability in demanding conditions.

Are Magnetic Connectors Compatible With Existing Medical Device Standards?

Yes, magnetic connectors can meet existing medical device standards. They provide reliable connections, enhance patient safety, and facilitate efficient maintenance, ensuring compliance with regulatory requirements while improving the overall functionality of medical equipment you design.

How Do Magnetic Connectors Contribute to Device Longevity and Reliability?

Magnetic connectors enhance device longevity and reliability by minimizing wear through fewer exposed parts, ensuring stable connections, and facilitating efficient maintenance. Their design prevents damage during use, promoting consistent performance in demanding environments.

Conclusion

In the rapidly evolving landscape of medical and wearable technology, the right magnetic connector can be a game-changer. Imagine the possibilities of enhanced patient care and streamlined device integration, all focusing on your choice of connector. As you explore further into this critical component, consider not just the specifications but also the potential for customized solutions. The future of health tech is at your fingertips—are you ready to make the connection that could redefine patient outcomes?